DeviceClip

- Home

- DeviceClip

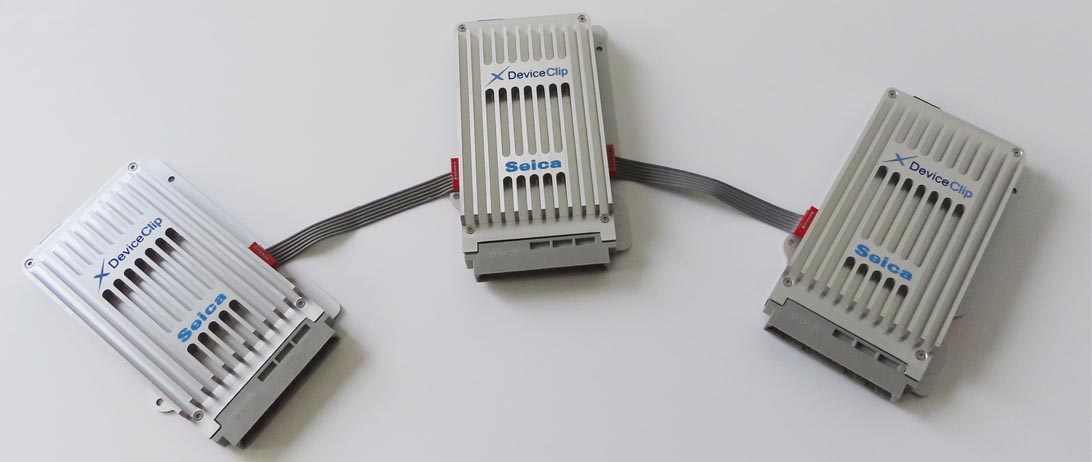

DeviceClip is the new ISP (In-system Programming) tool designed for devices and systems programming, highly modular and a virtually unlimited number of true parallel channels.

The Top 10 Reasons why DeviceClip is rapidly

becoming the standard-de-facto ISP tool

- Only One Tool: DeviceClip’s advanced architecture virtually supports every type of Flash-based Microcontroller, PLDs and Serial Memories. No need to choose a mix of several different ISP tools. DeviceClip supports, at the very same time, concurrent parallel programming of any mix of heterogeneous devices.

- Simultaneous Programming: DeviceClip’s multi-channel design allows programming operations to be performed in a true-parallel fashion without any type of restriction.

- High Channel Count: DeviceClip is modular. The number of channels (the number of target devices) of one unit is four. Several units can be natively cascaded to get a single programming tool provided of 8, 12, 16, up to 64 channels.

- Industry Fastest ISP: DeviceClip’s programming speed meets the maximum allowed by devices. Each target channel has the potential of supporting up to 200 Mbit/s bitrate.

- Robust Target Interface: DeviceClip, unlike most ISP tools, has an electrical interface with targets studied to withstand over-currents and over-voltages. I/O stages never break. Reliability is higher than any other commercial ISP solutions.

- Galvanic Isolation: DeviceClip is provided with solid state, micro-miniature relays for all signals of all channels of the target interface. On a specific software command, the tool goes in Galvanic Isolation mode, separating itself from the target devices and/or from the Host System (ATE or other).

- Compact Size: DeviceClip’s extremely compact size (4 channels in 107x60x15mm) allows its placement very close to the target devices. The tool can be easily integrated into Test Fixtures, keeping connections as short as possible.

- Stand-Alone Capability: DeviceClip offers both Host-Controlled (typically LAN or RS-232) and Stand-Alone operations. In Stand-Alone mode, no host is required, the tool is controlled by a opto-isolated, handshaking I/O interface.

- Ease of Use: DeviceClip was conceived and designed to provide users with an unrivalled flexibility. Every single detail was studied to simplify system integration (with ATE, PC, etc.). First in its category of tools, DeviceClip’s control panel is not a software application to be installed, but a standard HTML5 interface, perfectly compatible with all operating systems. Operations are controlled by means of a simple browser.

- Cost Reduction: DeviceClip’s advanced characteristics allow time-saving policies, increase reliability, keep set-up and operation industrial costs as low as never seen before for a professional- class tool.

For more technical information and the ISP Programmer Device list fill-in the form and a technical expert will call you back

EASE OF USE

DeviceClip is provided with an embedded control panel, thus no host software installation is required. Compatible with every operating system, all you need to fully control DeviceClip is just a browser. DeviceClip modular architecture allows the building of ISP tools provided with a large number of channels with no need of routers or switches. Only one host interface is required for managing all channels. And, when used in stand-alone mode, the host computer is not necessary at all.

LOWER OPERATION COST

Industrial ISP equipment has so far been implemented by using different, non universal tools from quite a few vendors. This leads to a high cost for ISP implementation on manufacturing lines. Different tools need more learning time (different interfaces, different commands, more spare parts, etc.).

TARGET PERSONALIZATION

DeviceClip runs a powerful server for the management of target variables (serial numbers, MAC addresses, calibration values or any other user-defined customization data). The result is a very easy target PCBA personalization. Target variables management can even be accomplished in stand-alone operating mode, when no host is connected. User’s pre-defined CSV files containing target board personalization data can be loaded on the SD card for being automatically managed by LynOS.

COMPACT

DeviceClip is very compact (only 100 x 60 x 10 mm), it was designed to be placed extremely close to the target (only a few millimeters away). This very compact size allows DeviceClip’s integration inside any test fixture. DeviceClip is a perfect solution for complex test fixtures, where space constraints often prevent the placement of tools close to the target.

ADVANTAGES

•Comprehensive device support

•Maximum programming speed

•Extremely high number of parallel ISP channels

•Higher reliability

•Lower manufacturing cost

RELIABILITY

All DeviceClip signals are very robust and protected from overvoltages or shorts from the target PCB. Operations performed by DeviceClip are time-stamped and saved in log files on the SD Card, always available for traceability and analysis. Status of programming operations is constantly monitored for any faulty condition, immediately communicated to operators through a series of alarms. Also, very short target wiring reduces signal noise while enhancing process reliability.

Privacy & Cookies

We use cookies for the proper functioning of the website and to keep track of how you interact with it, so that we can offer you a better and personalized experience. We will use cookies only if you agree by clicking on "Accept all" or you can manage the preferences of individual cookies from the "Customize" section.Privacy & Cookie Policy

Accept all

Reject allCustomize >

This website uses cookies

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Analytics" category . |

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Necessary" category . |

| cookielawinfo-checkbox-others | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category "Others". |

| viewed_cookie_policy | 1 year | The cookie is set by the GDPR Cookie Consent plugin to store whether or not the user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytical-cookies | 1 year | No description |

| cookielawinfo-checkbox-technical-cookies | 1 year | No description |

| DEVICE_INFO | 5 months 27 days | No description |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| Cookie | Duration | Description |

|---|---|---|

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| pll_language | 1 year | The pll _language cookie is used by Polylang to remember the language selected by the user when returning to the website, and also to get the language information when not available in another way. |